MANUFACTURING

Feb 29, 2024

by Joshua Rene

The Supply Chain Mastery of Zara: How Fast Fashion Stays Ahead

In the fast-paced world of fashion retail, agility and adaptability are paramount. Among the industry giants, Zara stands out for its unparalleled ability to deliver the latest trends to consumers with remarkable speed and efficiency. At the heart of Zara's success lies its innovative supply chain strategy, which has become the envy of competitors worldwide. In this blog post, we'll take a closer look at how Zara's supply chain operates and why it continues to set the benchmark for the fashion industry.

Fast Fashion Revolution:Zara's supply chain is synonymous with the "fast fashion" revolution, a concept pioneered by the company's founder, Amancio Ortega. Instead of the traditional fashion model, which relies on long lead times and seasonal collections, Zara operates on a fast-reacting, demand-driven approach. This allows the company to rapidly respond to emerging trends and customer preferences, ensuring that its stores are always stocked with the latest styles.

Vertical Integration:Central to Zara's supply chain strategy is its high degree of vertical integration. Unlike many of its competitors, Zara controls almost every aspect of its production process, from design and manufacturing to distribution and retail. By owning its production facilities and closely collaborating with suppliers, Zara can quickly translate design concepts into finished products, significantly reducing lead times and maintaining tight control over quality and cost.

Agile Manufacturing:Zara's supply chain is built around the concept of agile manufacturing. Instead of producing large quantities of clothing months in advance, Zara manufactures smaller batches of garments based on real-time demand signals. This allows the company to minimize inventory risk and respond swiftly to changing market dynamics, ensuring that its stores are stocked with the right products at the right time.

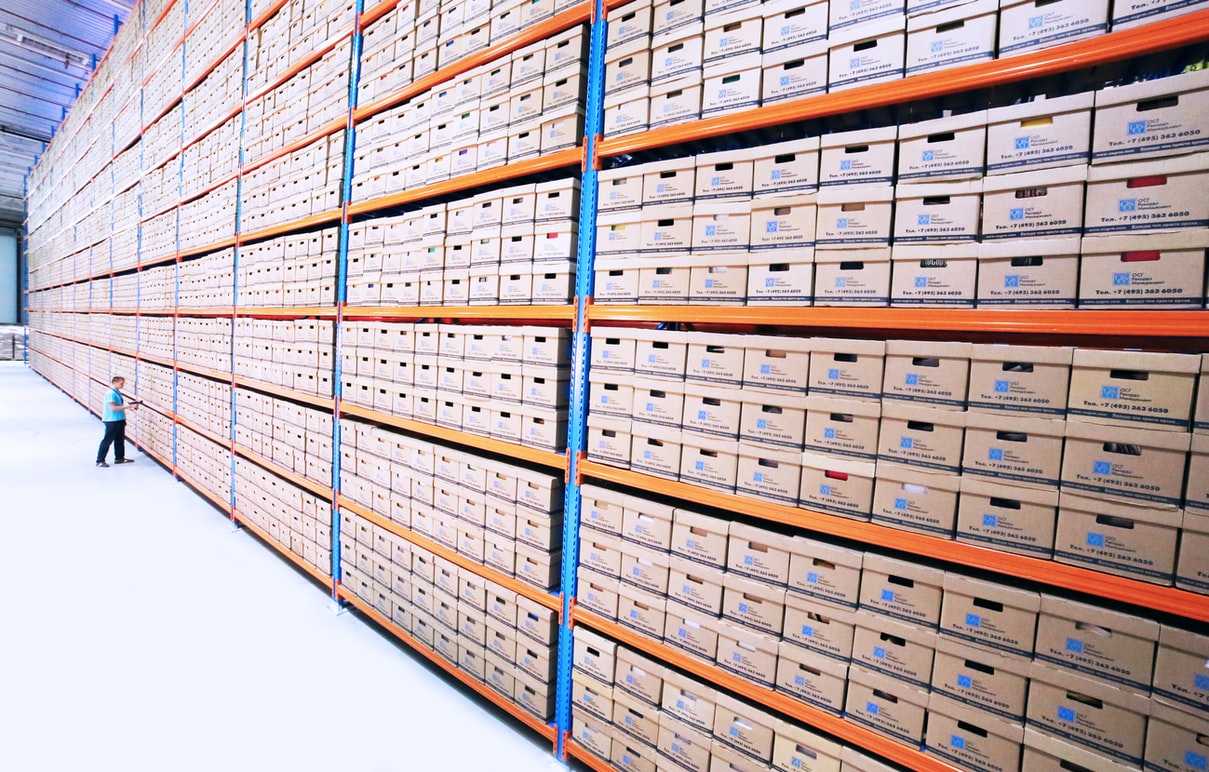

Quick Response Logistics:Speed is the hallmark of Zara's logistics operations. The company operates a network of highly automated distribution centers strategically located near its production facilities. These distribution centers use advanced technologies such as RFID tagging and automated sorting systems to streamline the flow of goods and minimize processing times. As a result, Zara can replenish its stores multiple times a week, ensuring a constant flow of new merchandise to meet customer demand.

Data-Driven Decision Making:Zara leverages data analytics extensively to inform its supply chain decisions. The company collects vast amounts of data from various sources, including sales transactions, customer feedback, and social media trends. This data is analyzed in real-time to identify emerging trends, predict demand patterns, and optimize inventory levels. By harnessing the power of data-driven insights, Zara can make informed decisions about product design, assortment planning, and allocation, driving sales and profitability.

Conclusion

Zara's supply chain prowess has redefined the fashion industry landscape, setting new standards for speed, efficiency, and responsiveness. By embracing vertical integration, agile manufacturing, quick response logistics, and data-driven decision making, Zara has cemented its position as a trailblazer in the world of fast fashion. As consumer preferences continue to evolve and competition intensifies, Zara's supply chain agility will remain a key differentiator, enabling the company to stay ahead of the curve and delight customers worldwide.